Some Of Sprue Bar Shut Off Devices

The conformally cooled sprue bushing was made as well as is marketed by PCS Co. (Fraser, Michigan), a maker and also supplier of mold and mildew components, mold and mildew bases, hot jogger items, as well as molding products for the plastic shot as well as die-casting sectors. The sprue bushing's trademarked spiral air conditioning network was produced through additive manufacturing by COMPUTER's partner/supplier.

Generated in H-13 device steel that's hardened and polished, these items are planned to be drop-in replacements for common B and also U collection chilly sprue bushings and are offered from PCS in 10 of market's most popular sizes, although the firm claims that custom-made sizes are readily available. COMPUTER additionally offers conformally cooled down entrance inserts for mold and mildews using warm joggers.

"Typically, we've seen 30 percent cycle-time savings, although savings can be as low as 15 percent and also as high as 80 percent relying on the application. sprue bar shut off devices." "This can be an excellent service for molders that need to lower cycle times to remain affordable in their markets," adds John Harding, PCS sales supervisor.

On the other hand, repayment can be actually quick, with some molders seeing an ROI in a matter of weeks or perhaps days depending on the application. With cooling bookkeeping for 70-80% of the shot molding cycle, if you can affect the air conditioning process, you can greatly boost cycle time.

Our Sprue Bar Shut Off Devices PDFs

"We really did not link it to existing water circuits (sprue bar shut off devices). All we needed to do was put a number of pipes right into the clamp plate to feed the water, and our customer included one more collection of jumpers in their water configuration to cool the sprue also faster. And also given that it has no O-rings, it doesn't leakage.

For larger work where you're making use of robot handling, it additionally would certainly keep your tools from getting gummed up. We'll most definitely suggest it to any person having a comparable issue." Midwest Mold Providers Inc. (Roseville, Michigan) constructs model as well as production devices with both aluminum as well as steel alloys for injection and also compression molders.

The business likewise is a prototype and also low-volume plastic part manufacturer-- with production runs of 50 to 10,000 shots or up to 100,000 parts yearly. Furthermore, Midwest sustains clients by using design, setting up, packaging and logistics/shipping solutions - sprue bar shut off devices. The Detroit-area firm was started in 1994 as a solution organisation supporting tier one/tier two custom-made vehicle molders with daily mold fixing as well as maintenance demands.

Although the automotive market remains crucial, the business has actually broadened into industries varying from mobile homes, bikes, agricultural equipment, grass as well as garden, as well as military/aerospace to medical/dental, telecommunications/electronics, as well as durable goods. Midwest is furnished with high-speed/multi-axis CNC mills, cord EDMs, and devices for grinding and also component appearing, all run by competent, licensed machinists.

Unknown Facts About Sprue Bar Shut Off Devices

The firm uses Strong Works CAD, which can translate documents from Car CAD, CATIA, Softech, Unigraphics, Secret Developer, Pro E, SDRC Suggestions, ACIS, Cimatron, Step, Parasolids, Solid Edge, Solid Works, IGES/VDA-FS, Delcam DGK, Rhino and a lot more. Not just is Midwest Mold ISO 9001:2015 certified and also able to hold EDM and also grinding resistances to ± 0.0005-inch/ 0.01 mm, yet the business also is a participant of Michigan's Shore to Shore Tool & Die Joint (MCCTD), which consists of 13 firms that joined forces in 2008 to expand their own operations as well as support other members in an internationally affordable market.

The relevance of plastic part traceability and also exactly how to accomplish it. Easy cyndrical tube estimations offer great first look comparisons for correct sizing when moldmakers are considering one of the most ideal side-action option early in the mold and mildew layout.

Approximate. Rs 1.28 Lakh/ Piece Obtain Most Recent Cost Item Details: Minimum Order Quantity 1 Item Kind Automatic Number Show Size Twin Display Controler Kind Analog Brand Name Dydac Controls Dydac uses Hot Runner Controller utilizes high-intellect microprocessor innovation to provide trustworthy, specific temperature control, these cutting edge controllers are our most user-friendly control modules yet.

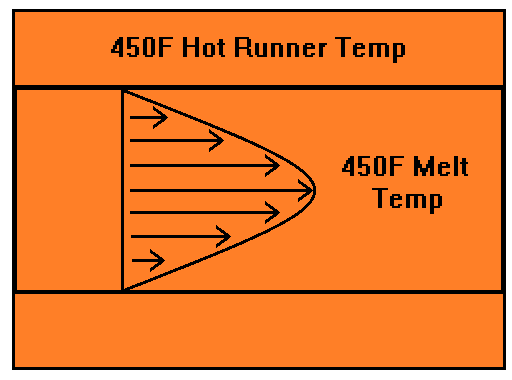

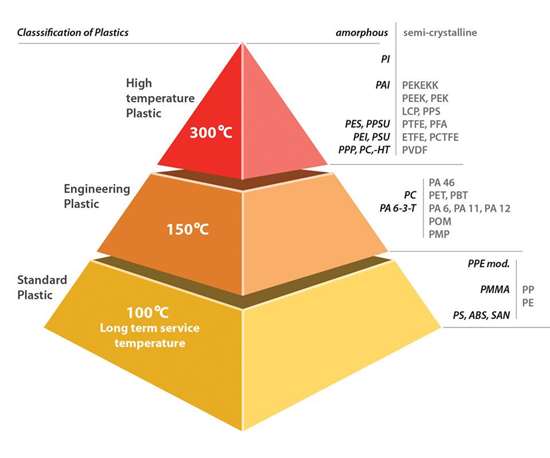

Warm Runner Controllers supply reputable temperature level control for runners/spineless injection mold and mildews, equipment nozzles, hot sprue bushings, or any kind of various other application needing thermocouples to keep track of temperature. Dydac hot jogger controllers supply all the advantages of a totally incorporated controller in a compact plan at a cost effective price. This new control system provides Single to 48 areas of control as well as is geared up with 16 amps and 30 per zone, making it versatile sufficient to deal with a wide range of applications.

Things about Sprue Bar Shut Off Devices

Precise control is attained via the application of Active Thinking Technology. Dydac uses a mix of software and equipment style, which is distinct to the line of product. It is identified throughout the market for its accuracy, uniformity, and also repeatability. Various Other Information: Microprocessor Based Car-- Song PID Temperature Controller Accepts J, K, R, S, T Type Thermocouple( Soft Begin) cook out function stops wetness at start-up Auto/Manual Transfer The precision of/- 1 Deg.

Twin displays for Process and also Set Temperature Levels High Rate Integrates 16 A defense Fuses. New Series with Short Circuit defense of Power Modules by C Contour MCBLatest Generation PID algorithm. Power Controller can take 3600 or 7200 Watts at 240 VACIn the case of thermocouple Failure, you can establish the Power Manually by not quiting the manufacturing.

PID Temperature controller has bar chart sign of portion result mosting likely to heaters. PID Temperature Level Controller is CE Compliant as well as Phase Angle Power Controller is CE Compliant. The Power Controllers are Stage Angle Fired as well as vary Power Controllers which provides as much Power to the Heating systems as needed to keep the Temperature hence saving the Power (Energy Preservation at Establish Factor) as well as increasing the life of Heating units and also Less Production Break Down.

why not try this out go to website go to my blog